Home

Solutions

Products

Services

About

Careers

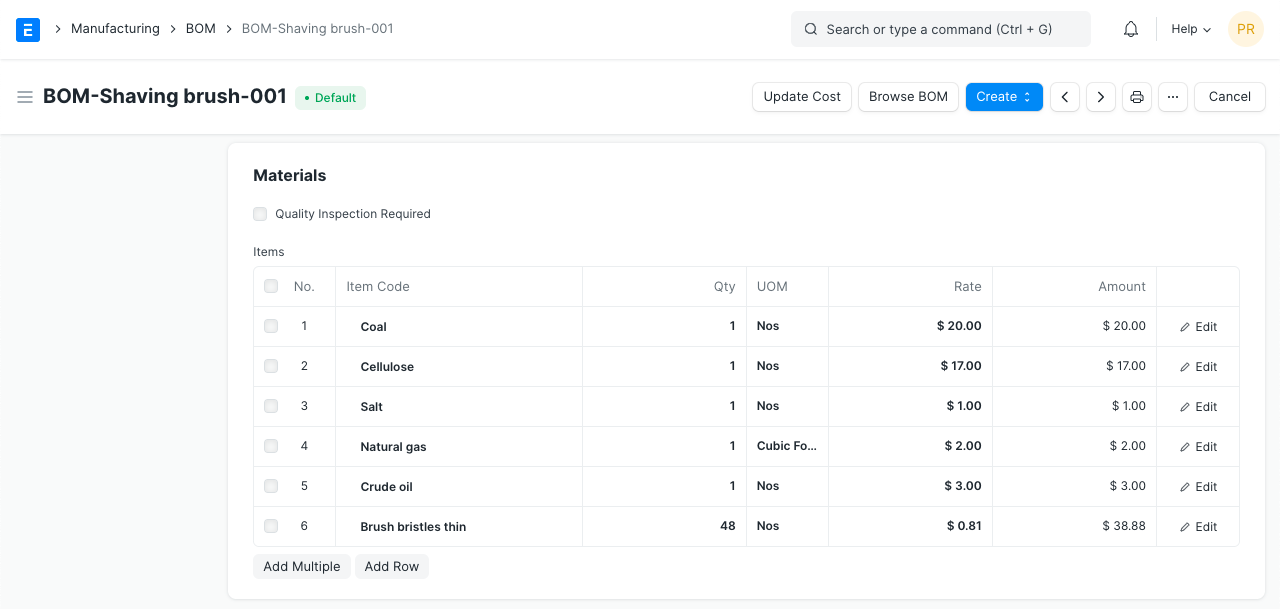

Supercharge Your Manufacturing with BOM

A Bill of Materials (BOM) is a list of all the raw materials, sub-assemblies, and items required to manufacture a finished product. It can contain multiple levels of sub-assemblies and items.ERPNext also allows users to create multi-level BOMs. This means that a BOM can contain other BOMs. This is useful for complex products that require multiple sub-assemblies.

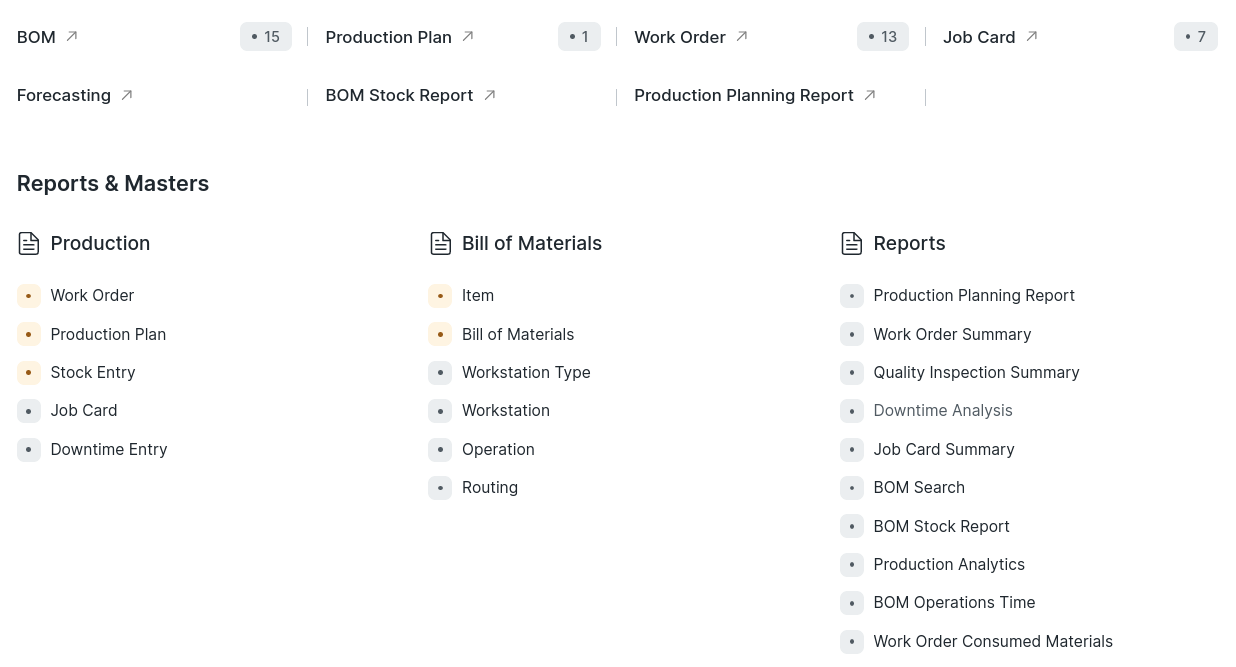

Track all the production metrics

A work order in ERPNext is a document that is used to track the production of a specific item. It includes information such as the item to be manufactured, the quantity to be manufactured, the planned start and end dates, the actual start and end dates, the status, and the quantity produced.

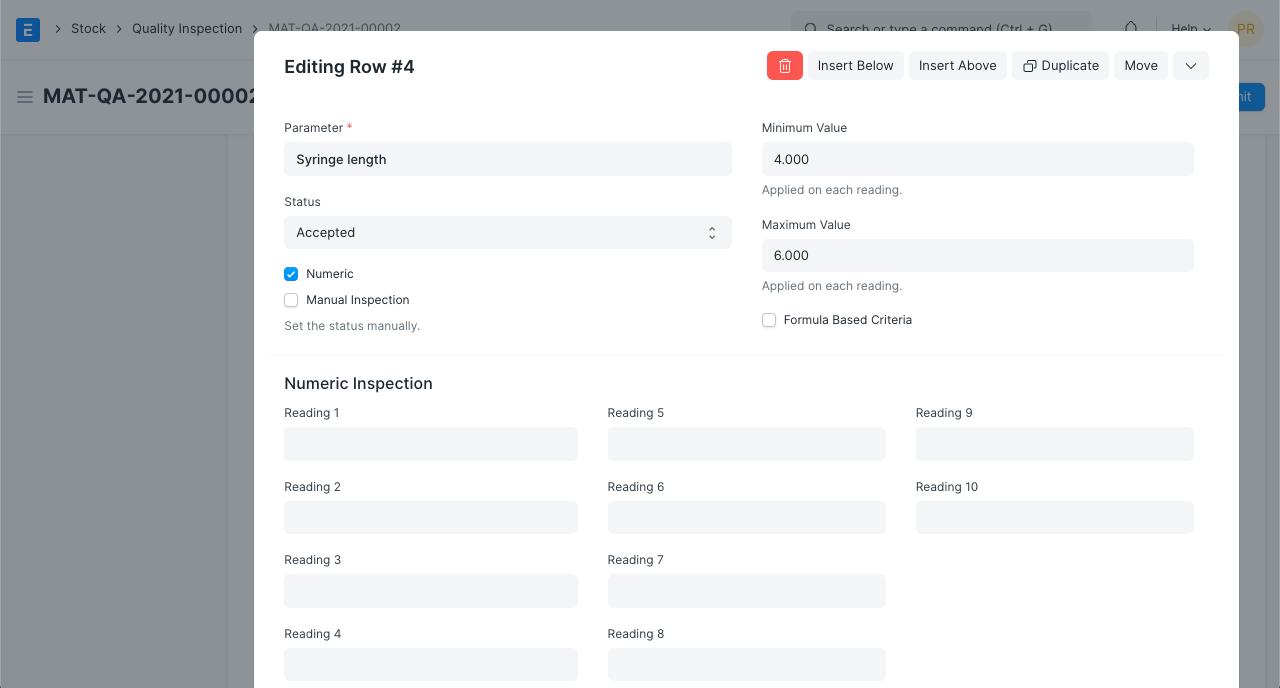

Take Your Quality Management to the Next Level

Quality Inspection is a process for ensuring the quality of incoming, outgoing, and in-process inventory. It allows businesses to define inspection criteria, create quality inspection templates, and record quality inspection results. It is a powerful tool that can help businesses to improve their quality performance, reduce the cost of defects, and increase their customer satisfaction.